American Malting and Grain Growing for Craft Beer

With more than 4,000 craft breweries in the United States, it’s hard not to talk about…

With more than 4,000 craft breweries in the United States, it’s hard not to talk about the origin of the beer in your glass. Now there’s a new development in the industry that has enthusiasts, especially homebrewers, talking about where the grains in that beer came from. That development is the micromalting movement, and it’s quickly sweeping the country.

Craft-sized operations are malting and roasting locally grown grains in small batches before they turn over their finished products to homebrewers, professional brewers, and distillers for mashing into wort. As they establish themselves in various agricultural pockets of the U.S., craft maltsters are further defining what it means to drink local.

Rooted In Homebrewing

![]() When Jason Cody and his family launched Colorado Malting Company in Alamosa, Colorado in 2008, an enthusiastic response from homebrewers caught them by surprise. Homebrewers wanted to experiment with the variety of flavors that CMC’s malt would yield, and they wanted to support a local business.

When Jason Cody and his family launched Colorado Malting Company in Alamosa, Colorado in 2008, an enthusiastic response from homebrewers caught them by surprise. Homebrewers wanted to experiment with the variety of flavors that CMC’s malt would yield, and they wanted to support a local business.

“The homebrewing community usually centers around a craft brewery because they like to drink craft beer, visit with the brewers, share hops and yeast,” said Cody. In this case the homebrewers centered around a craft malting company.

“Homebrewers started to discover that we were around – a lot of them came across our website surfing the Internet — so we picked the ball up quickly and took care of them,” Jason said. “I remember lots of experiences taking trips to Denver in a pickup truck full of grain to a homebrewer’s house.”

The demand for Colorado Malting’s base malts eventually meant Jason and his staff couldn’t deliver to homebrewers’ doorsteps anymore. Homebrewers couldn’t get enough of Colorado Two-Row Malt and Colorado Pilsner Malt, specialties such as Colorado Belgian Chocolate Malt and Colorado Malted Red Wheat – or malted gluten-free millet and buckwheat. In 2012, the company hired an official Homebrew Advocate, Jason’s uncle Tim Cody, whose exclusive job at the time was to answer inquiries from homebrewers. “At that point we were shipping to homebrewers directly,” said Tim. “I cleaned, packaged, and shipped every bag of malt that was sold.”

“One of Tim’s responsibilities is to go the extra mile for homebrewers,” Jason said. “He spends three to four hours every day fielding emails from brewers all over the country and the world. He takes care of every individual person with technical information and quotes on products.”

Further increase in demand means Jason and Tim can no longer ship directly to homebrewers. Instead they’ve created partnerships with several of the state’s homebrew supply shops where they can sell their malt in greater volume. Tim’s title has changed to Gatekeeper of The Malt and he now functions as an account executive.

Colorado Malting ships roughly 60 percent of its malt to professional brewers, usually working with brewhouses of less than 30 barrels, and the remainder goes to homebrewers.

Despite Colorado Malting’s evolving business model, the interest it gets from homebrewers has never faltered. Perhaps that’s because CMC gives them the ability to produce a huge variety of beer flavors that had not yet been available to them. “Everyone’s malt generally comes from the same places – big malthouses overseas,” Jason said. “With our malt, people are actually getting to brew beer that’s different; they’re able to taste the region. We’re presenting products that are completely unique in every way, and that means the possibilities are endless for homebrewers.”![]()

Homebrewing plays a large part in the company’s research and development. When the CMC first considered malting sunflowers as a gluten-free offering, it was the local homebrew community that helped to formulate the process. “Sunflower turned us on to the fact that you can use gluten free grains not typically associated with beer-making to make beer,” said Jason. “Sunflowers’ complex proteins help head retention in gluten-free beer. It was homebrewers who helped us understand that. A lot of them are chemists — it’s like having a lab in everybody’s garage.”

There are labs in Colorado Malting’s garage, too, so to speak. The CMC staff brews on malthouse homebrew equipment with each grain they malt. “We brew for product quality control,” said Tim. “That gives us numbers to pass on to homebrewers of what they can expect of all the different grains that we’re malting.”

“We also like to drink our own beer,” adds Jason.

Colorado Malting maintains good relationships with homebrewers through educational programs as well as through homebrew supply shops. This spring the company helped launch the San Luis Valley Homebrewers Association and this fall it will host the Rocky Mountain Malting Technical Institute. The upcoming institute will bring together industry experts, such as Dave Thomas, author of the Craft Maltsters’ Handbook, and Bill Owens, president of the American Distilling Institute. They will conduct seminars about the history of malt, the state of the craft malting industry, and how to malt your own barley at home.

“We’re expecting a large group of homebrewers to come to the Malting Institute,” said Jason. “To be able to malt at home is the next thing for homebrewers to get their heads around. You can buy raw grain from a farmer and make it into a beer… how cool is that?” Colorado Malting’s goal was always to connect the producer to brewers and distillers, Jason said, and also to give brewers, homebrewers, and distillers tools to take control of their craft. That same philosophy applies at many of the craft malting companies popping up throughout the U.S.

Six-Row In The Southeast

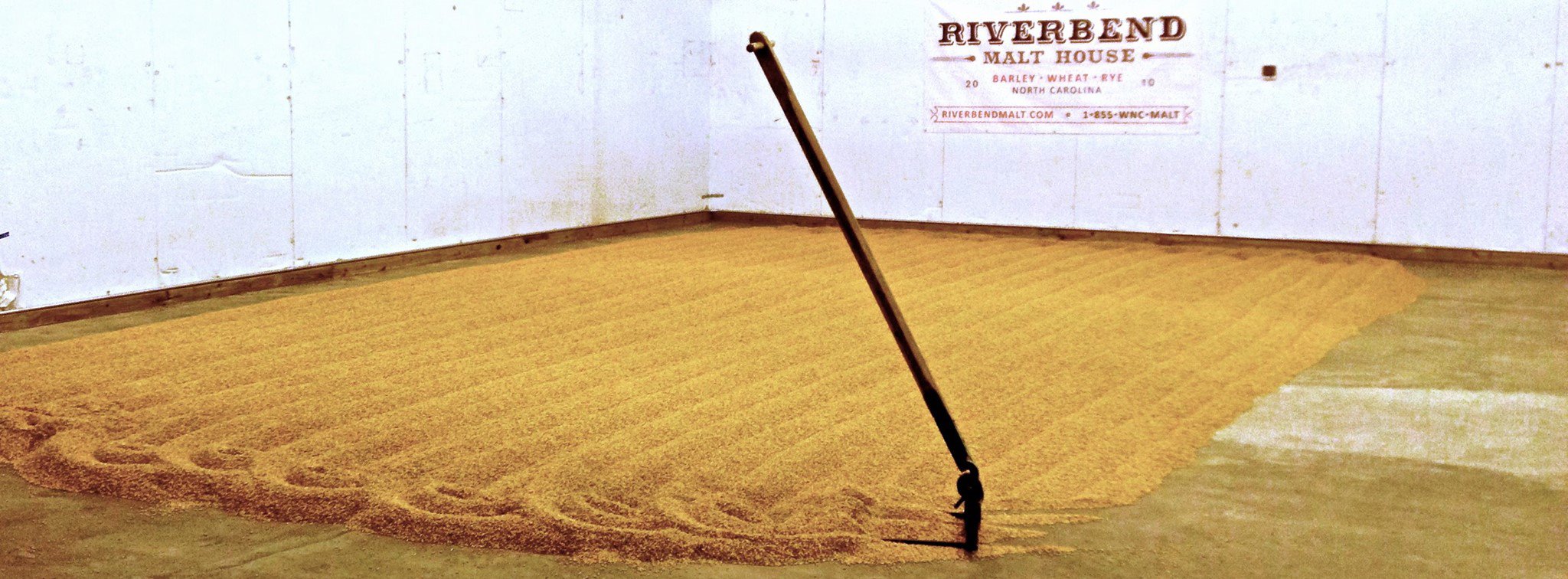

![]() “Following the trend of craft breweries, I see a lot of states getting micro-malthouses in their areas,” said Brent Manning, co-owner at Riverbend Malt House in Asheville, N.C. Riverbend opened in 2011 and quickly generated interest from nearby craft brewers looking to source their grain locally. The company is 1,500 miles away from the closest major malthouse and just down the road from Asheville’s 19 craft breweries (and counting), many of which are customers. Not to mention it is one of the only houses in the country malting six-row barley.

“Following the trend of craft breweries, I see a lot of states getting micro-malthouses in their areas,” said Brent Manning, co-owner at Riverbend Malt House in Asheville, N.C. Riverbend opened in 2011 and quickly generated interest from nearby craft brewers looking to source their grain locally. The company is 1,500 miles away from the closest major malthouse and just down the road from Asheville’s 19 craft breweries (and counting), many of which are customers. Not to mention it is one of the only houses in the country malting six-row barley.

Also called winter barley, six-row barley is planted in late fall and harvested the following summer. It’s indigenous to the Southeast region and better suited for North Carolina’s heat and humidity than its tworowed sister. “We surprise people because we use six-row barley,” said Manning. “A lot of people associate it with dry, husky flavors, and not a rich, malt bready flavor profile. We’re able to really draw out a lot of rich, malty, sweet flavors though. We’ve found that you can make a nice full-bodied pale ale, whether it’s session strength or a big black IPA.”

“We built clientele through education,” Manning continued. “Sometimes we homebrewed beer with our own products and poured it on tours for potential clients. Within a year and a half of opening, we were swamped with demand. We spend a lot of time with shovels in our hands. Today we shoveled 8,000 pounds of malt before lunch.”

Going Gluten Free

Grouse Malting and Roasting Company in Wellington, Colorado is also building its market through education. This exclusively gluten-free malting company was founded by Twila Henley, whose interest in gluten-free beer started during her graduate studies at Colorado State University. She was studying food science and food safety when she met a classmate who had been diagnosed with Celiac disease. “I was struck by her dedication to this diet,” said Henley about her classmate. “I remember thinking, ‘There’s gluten-free bread and pizza crust, so there’s got to be gluten-free beer on the market.’”

There was gluten-free beer, but it didn’t taste good. “I did some taste tests of gluten-free beers and I was appalled that they tasted so terrible,” she said. “They didn’t have the quality characteristics of beer made with malted barley. So I made it a personal crusade to develop a gluten-free beer that tasted great.”

That’s when Henley started home-malting. She called a local farmer and learned that Colorado is the largest producer of millet in the United States. “I started sprouting millet in my kitchen,” she said. “I had a friend with a homebrew system, so I malted, he brewed, and we were pretty impressed by our attempts at brewing beer with gluten-free malt.”

Much like Colorado Malting, Grouse got up and running with the help of homebrewers who brewed with the company’s malted millet, oats, buckwheat, and more. They gave feedback about how it performed in beer and provided beer recipes using Grouse’s gluten-free grains.

![]() “My goal as a craft maltster is to bring value to the industry by providing the highest-quality malt and roasted grains,” said Henley. “From the get-go Grouse offered specialty malts — we wanted to supply roasts that could make dark beer, for example, which isn’t a common variety of gluten-free beer.”

“My goal as a craft maltster is to bring value to the industry by providing the highest-quality malt and roasted grains,” said Henley. “From the get-go Grouse offered specialty malts — we wanted to supply roasts that could make dark beer, for example, which isn’t a common variety of gluten-free beer.”

Grouse now provides gluten-free malts that go into several commercially made beers, such as Watchstander Stout by Ghostfish Brewing Company, a small-batch brewer in Seattle, and Oatmeal Stout by Shadows Brewing Company, a brewpub in Cheyenne, Wyoming. “Grouse is helping to change the paradigm of peoples’ perceptions of gluten-free beer,” Henley said.

Rice on the New Frontier

Another malting company changing the way people perceive gluten-free beer is Eckert Malting & Brewing in Chico, California. The facility is the first in the world to exclusively malt and roast rice as a grain for brewing.

The owner Jim Eckert, a homebrewer for more than 40 years and a professional agriculture researcher for 30 years, first started brewing with rice when his wife discovered she had intolerance for gluten. She shared Twila Henley’s disappointment in the flavor of commercially available gluten-free beers and challenged her husband to brew a gluten-free beer for her that actually tasted good. So Eckert started with brown rice syrup and eventually switched to all-grain batches of rice beer. “After two years, I decided my product was good enough to put on the market,” said Eckert, which he did.

![]()

“As a brewer of rice beer I had to build a malthouse first because at the time no one else was doing that,” Eckert explains. He started roasting a variety of different rices — light offerings such as biscuit rice and crystal rice as well as dark rice and the even darker gas hog rice. He brewed into a full spectrum of light to dark beers, including a hoppy black ale. “Colored rice malt adds interesting character to beers that wouldn’t exist otherwise,” he said.

To date, Eckert has six rice beers available at his malthouse and brewery, including a light lager and a dark lager, which are bottled and will eventually be kegged for local accounts. As far as the malt goes, Eckert will ship to any interested brewery or distillery, near or far.

“It’s been slow convincing people that you can brew with rice,” Eckert said. “The local homebrewers were very reluctant initially, but still curious. They had lots of questions. They pushed me more than anyone else has pushed me. Today homebrew stores purchase the majority of my malt.”

With support from experimental homebrewers and interest from several craft breweries and distilleries, Eckert’s rice is fundamentally changing the gluten-free brewing game. Not to mention his beers are broadening the scope of gluten-free products available on the market.

A Guild of Their Own

Alongside Colorado Malting, Riverbend Malt House, Grouse Malting and Roasting, and many others, Eckert has joined a new trade association for craft maltsters. He likens the North American Craft Maltsters Guild to the Brewers Association and statewide brewers guilds. He predicts a boom in membership. “Together we’re discovering we can do things that big malthouses don’t do, and we’re ending up with much more distinct, local beers,” said Eckert. “We’ve grown tremendously within the year I’ve been involved, taking on 20 or more new members.”

Colorado Malting’s Jason Cody agrees there’s plenty of blue sky when it comes to growth. “I really see craft malting and small malthouses like ours showing up in every nook and cranny. This is how beer used to be made — what we’re doing is the roots of beer.”

Comments 0

No Readers' Pick yet.