Start 14-Day Trial Subscription

*No credit card required

Everything You Need to Know About Hops (and Much More)

Here's an in-depth look at everything you need to know about hops, as well as how four popular hop varietals affect flavor, aroma and other characteristics.

With IPA as the leading craft beer style in America, even casual craft beer drinkers are aware that hops provide the bitter flavor in their favorite beers. But the way that hops are selected and their flavors and aromas are extracted is less well-known – more the territory of “mad chemist” brewers, who must draw on a knowledge of biology, chemistry and math to craft the next big thing. In fact, the ever-evolving chemistry between hops and beer is one of the most fascinating and intricate aspects of the craft beer universe. Here's an in-depth look at everything you need to know about hops as well as how four popular hop varietals affect the flavor, aroma and other characteristics of beer.

THE BASICS

Hops are the cone-shaped female flower of the vine-like plant humulus lupulus, and the important ingredients are concentrated in the cone’s lupulin glands. Hops are harvested from bines (aka tendrils), then dried and processed into pellets, plugs, extracts, or left in their cone form.

During the brewing process, hops are added at the beginning of the boiling stage to add bitterness to a beer's flavor and more are added at the end of the boil for aroma and flavor. Hops also act as a preservative by inhibiting spoilage bacteria during a beer’s shelf life and they help to stabilize foam.

The four basic ingredients in brewing: malted barley, hops (in pellet form), a yeast slurry and water. Like scientists who experiment to learn how different substances interact, combine and change, modern brewers are known to get creative with any type of hop at any stage of the brewing process.

Photo Courtesy pFriem Family Brewers

Europeans probably began cultivating hop flowers for beer around the eighth or ninth century, and the hop heads of the 14th and 15th centuries are to thank for hop leaves overtaking other herbs and spices when it comes to flavoring beer. Today there are many dozens of varietals, sometimes labeled “old world” and “new world.” Ideal growing conditions exist between the 35th and 55th parallels in both hemispheres, so a few regions produce the majority of the world’s hops. The United States (“new world”) and Germany (“old world”) are the leading producers.

Bruce Wolf, owner of Willamette Valley Hops, said that the growing region can have a significant impact on hop characteristics. “Not just the dirt, but the climate and the weather pattern throughout the spring and summer dictates a lot of what the hop profile is,” he said. So the challenge, he noted, is ensuring consistency for craft brewers who depend on certain hop varietals for their beers.

THE CHEMISTRY OF EXTRACTION

Those early hop heads knew hops made beer awesome, but thanks to science, we have a better understanding of why.

There are two general categories of hops: bittering hops, which have a higher alpha acid content and contribute more bitterness but tend to impart a less refined flavor and aroma; and aroma hops, which are lower in alpha acids, but contribute desirable flavor and aroma characteristics. Some hops are dual-purpose.

A sample is prepared for the analysis of bitter acids in hops at Haas, a hops supplier, hops breeder and research brewery.

Photo Courtesy Haas

Alpha acids such as humulone, adhumulone and cohumulone are very important to understanding how hops add bitterness. They are expressed in a weight percent generally ranging from 2 to 19 percent. Many European hops have alpha acids in the 5 to 9 percent range, which means these hops are used for aroma and flavor, or they may be dual-purpose. Newer American hop varietals are typically higher in alpha acids, around 8 to 19 percent, and contribute more bitterness.

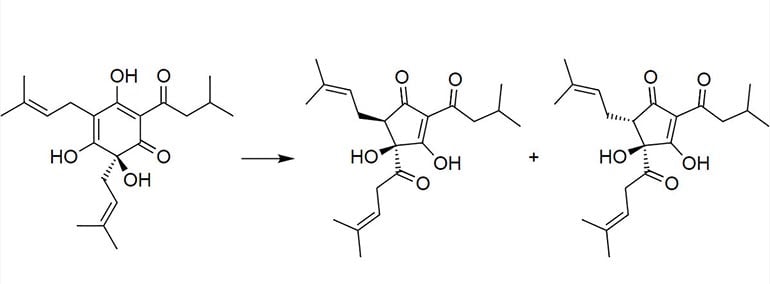

Boiling extracts the desired characteristics. In the case of bittering hops with higher alpha acids, longer boils (usually 60 minutes or more) will cause the alpha acids to isomerize. That’s the process by which a molecule is transformed into another molecule with the same, but rearranged, atoms.

With this chemical switcheroo complete, the alpha acids are now iso-alpha acids, also known as isohumulones. These bad boys are responsible for the bitter flavor of beer. So beers with high IBU counts (international bitterness units) are those that have a higher concentration of iso-alpha acids. The most common way to measure IBUs is called spectrophotometry, which can also be used to measure a beer's SRM (Standard Reference Method for specifying color) and usually involves fairly expensive equipment.

Humulone Isomerization

Hops also contain beta acids. Instead of isomerizing during the boil, they tend to oxidize, a process involving the loss of electrons that can result in an unpleasant flavor. Brewers generally prefer hops with a low beta acid content for this reason, though beta acids can contribute aroma if added at the right time.

In the case of aroma hops, the goal is to extract the volatile essential oils that are responsible for the aroma or flavor character of a beer. Not as much is understood about the chemistry of hop essential oils in comparison with hop acids because of their complexity and the changes that take place during brewing.

Because the oils are largely lost by steam evaporation during the boil, aroma hops are often added at the end for about 5-15 minutes. Dry hopping − the practice of soaking hops after the wort has cooled in the fermenter – helps extract these oils and is understood to contribute a more assertive and fresh hop aroma and flavor. Recent hop research has looked at whether dry hopping really makes a difference, and the results are mixed.

At Haas, a researcher prepares to analyze hop essential oils.

Photo Courtesy Haas

It’s worth noting that hop extracts – vs. pellets, plugs or whole cones – are treated a little differently in the brewing process. Isomerization can be achieved by adding other chemical compounds (such as alkalis or magnesium salts) or by exposure to a specific wavelength of light, instead of through boiling. Iso-alpha acid extracts are also available but are added later in the process, usually during secondary fermentation. Extracts have become more popular in recent years because they have a longer shelf life, do not require refrigeration, cut down on boiling time and there is no need to strain used hops afterward.

While extracts are a popular tool to increase flavor and aroma, they’re not necessarily a perfect replacement. Tim Kostelecky, a hops and brewing technical specialist with supply and research company Haas, said that hop solids (which are absent from extracts) contribute to the characteristics of “hop forward” styles.

“The hop solids contain many water soluble compounds that can contribute additional flavor and mouthfeel beyond what is expected typically from hop resins,” he said. These compounds react in unique ways to create specific hop characteristics, such as polyphenols, which he said are “a secondary source of hop bitterness and astringent ‘tannin’ mouthfeel.”

Cryo Hops are a relatively new development in hop processing. According to Yakima Chief – Hopunion, the proprietary cryogenic separation process produces a concentrated product, which is used in brewing to enhance hop flavor and aroma.

Photo Courtesy pFriem Family Brewers

Comments

Pages